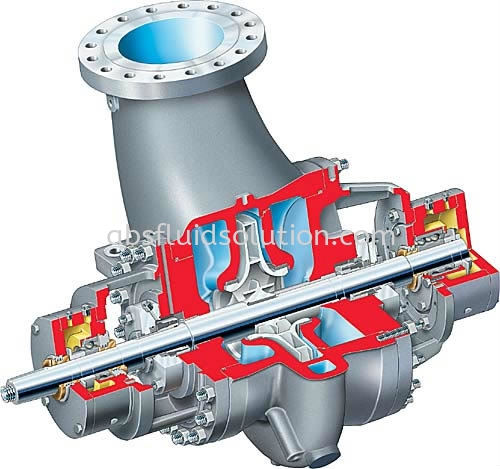

HDX ISO 13709/API 610 (BB2) Between Bearings, Single Case, Radially Split, Single Stage Double Suction Pump

Specifications

Details

Brands:

IDP

Applications:

Nuclear Service, Hydrotreating, Offsites and Waste Treatment, Residuum and Heavy Oil Upgrading, Dewatering and Water Supply (mining), Water and CO2 Injection, Industrial Gases, LNG, Auxiliary (chemical), Water Supply and Distribution (water), Catalytic Cracking, Distillation (oil and gas), FPSO, Gas to Liquids, Heat Transfer Fluids, Heavy Oil, Oil Sands and Shale, Hydrocracking, Boiler Feed Booster, Boiler Feed (pulp and paper)

Industries:

Power Generation, Pulp and Paper, Oil and Gas, General Industries, Mining, Water Resources

Standards:

API682, API610

Dual Volute Centerline Supported Casing, combined with a stiff shaft design, ensures full compliance with ISO 13709API 610 specified nozzle loads, vibration and shaft run-out requirements.

Double Casing Covers provide easy maintenance.

Double Suction Impeller minimizes thrust problems, reduces NPSH requirements and allows mechanical seals to operate at equal and low pressure.

Dynamically Balanced Rotor ensures smooth operation for longer mechanical seal and bearing life. TIR Verifications ensure optimum mechanical performance throughout the operating range.

360° Support Bearing Housings are made of carbon steel to provide added stiffness and reduced vibration.

ISO 21049/API 682 seal chamber accommodates a wide variety of seal configurations.

High Pressure model (HPX-H) available.

Operating Parameters

- Flows to 4100 m3/h (18 000 gpm)

- Heads to 450 m (1500 ft)

- Pressures to 42 bar (610 psi); 100 bar (1450 psi) with HDX-H model

- Temperatures to 450°C (850°F)

View more about HDX ISO 13709/API 610 (BB2) Between Bearings, Single Case, Radially Split, Single Stage Double Suction Pump on main site